Zero Discharge Systems (ZDS), often referred to as Zero Liquid Discharge (ZLD) systems, are vital in industries where water conservation, sustainability, and regulatory compliance are priorities. These systems recycle and reuse wastewater, ensuring no liquid waste is discharged into the environment.

Why Regular Upkeep is Essential for Zero Discharge Systems

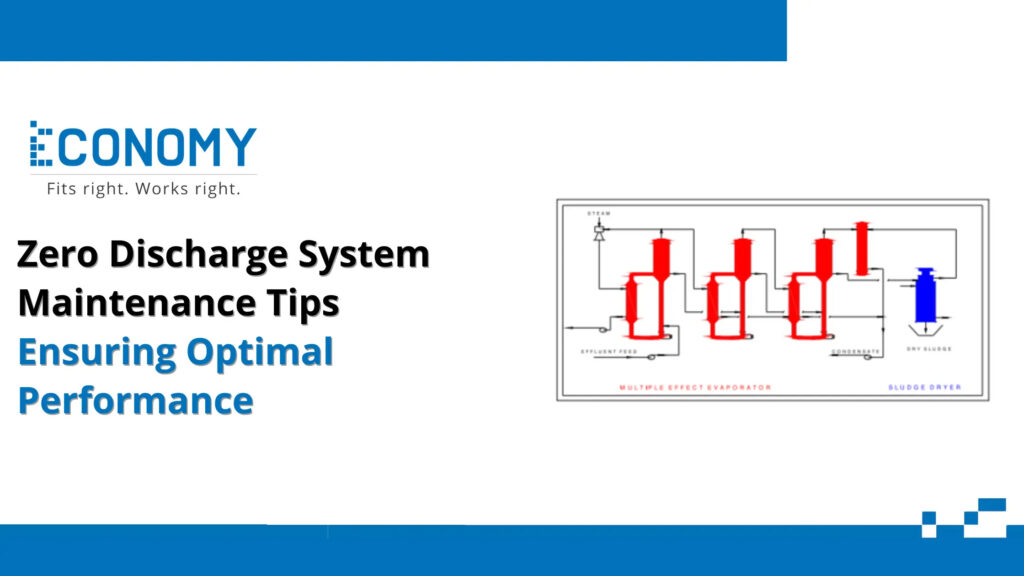

Zero Discharge Systems integrate multiple processes such as reverse osmosis, evaporators, crystallizers, and filtration units. Each component plays a critical role, and even a minor malfunction can disrupt the entire system. Regular maintenance is crucial for several reasons:

Efficiency: Clean and well-maintained equipment consumes less energy and operates at maximum capacity.

Longevity: Preventive upkeep reduces wear and tear, extending the life of expensive components.

Compliance: Regulatory standards for wastewater discharge are strict. A malfunctioning ZDS risks non-compliance and legal penalties.

Cost Savings: Preventing breakdowns is far less expensive than emergency repairs or replacements.

Sustainability: Consistent operation ensures industries meet their environmental commitments by minimizing waste and maximizing water reuse.

Key Tips for Zero Discharge System maintenance

To keep Zero Discharge Systems performing at their best, industries should follow a structured maintenance routine. Here are some essential tips:

Regular Cleaning of Membranes and Filters

Fouling and scaling are common problems in membranes and filters. Periodic cleaning with recommended chemicals prevents blockages and improves system efficiency.

Monitoring Water Quality

Continuously check feedwater quality, as impurities like silica, hardness, or organic matter can damage system components. Pre-treatment systems should also be inspected regularly.

Inspecting Pumps and Motors

Pumps and motors are the backbone of ZDS. Lubrication, vibration checks, and alignment inspections should be part of routine maintenance to prevent breakdowns.

Calibration of Sensors and Instruments

Flow meters, pH sensors, conductivity probes, and pressure gauges must be calibrated to ensure accurate monitoring of process parameters.

Descaling Evaporators and Crystallizers

Mineral build-up inside evaporators can reduce heat transfer efficiency. Scheduled descaling prevents energy losses and damage.

Checking Piping and Valves

Look for leaks, corrosion, or blockages in pipelines and valves. Even small leaks can escalate into bigger problems.

Answers for Normal Issues

Despite regular upkeep, Zero Discharge Systems may face some recurring challenges. Here’s how to address them:

Scaling and Fouling: Use anti-scalant dosing and periodic chemical cleaning to minimize build-up.

Membrane Damage: Replace membranes showing signs of reduced rejection efficiency or physical wear.

Pump Failures: Ensure proper lubrication and avoid operating pumps at conditions outside their design limits.

Sensor Malfunctions: If readings are erratic, recalibrate or replace faulty sensors.

High Energy Consumption: Inspect for fouling in heat exchangers or evaporators, as this often causes unnecessary energy use.

Unexpected Shutdowns: Check control systems for errors and ensure backup power supplies are functioning.

Best Practices for Feasible Support

Effective maintenance goes beyond reactive fixes—it requires adopting best practices that support long-term feasibility and performance.

Implement Preventive Maintenance Schedules: Follow manufacturer-recommended intervals for cleaning, inspections, and servicing.

Train Personnel: Skilled staff familiar with system operation can identify issues early and prevent costly damage.

Use Genuine Spare Parts: Substandard parts may offer short-term savings but often compromise system integrity.

Devices and Assets for Upkeep

Having the right tools and resources is essential for efficient system maintenance. Some key devices and assets include:

Chemical Cleaning Systems: Portable cleaning units designed for membranes and heat exchangers.

Water Quality Analyzers: Tools for measuring pH, conductivity, total dissolved solids (TDS), and turbidity.

Ultrasonic Leak Detectors: For early detection of pipeline leaks.

Vibration Analyzers: To monitor pump and motor health.

Maintenance Management Software: Digital platforms to schedule tasks, track history, and manage spare parts inventory.

These assets reduce downtime, enhance accuracy in inspections, and streamline maintenance operations.

Guaranteeing Ideal Execution Through Customary Support

The success of a Zero Discharge System lies in consistent, proactive upkeep. Customary support ensures that each component—from membranes to evaporators—functions as designed, delivering high recovery rates and reliable water reuse. Industries that prioritize regular maintenance not only safeguard compliance and sustainability but also achieve better cost-efficiency and equipment reliability.

Conclusion

Zero Discharge Systems are indispensable in industries striving for sustainability and compliance with environmental standards. However, their complexity demands disciplined maintenance practices. From monitoring water quality and descaling evaporators to training staff and leveraging digital tools, every step in upkeep contributes to smoother operations and optimal performance.